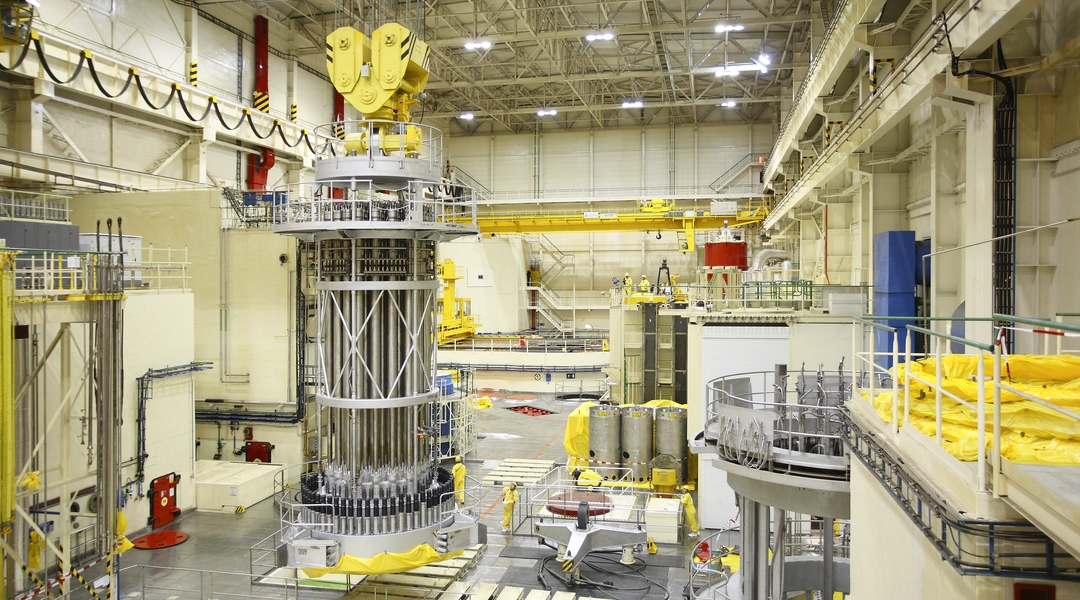

Comprehensive maintenance of the primary circuit equipment

ŠKODA JS a.s. provides operating nuclear power plants with a wide range of services to ensure their reliable operation. We offer our customers comprehensive, advanced solutions for highly effective operation of nuclear power units over their entire lifetime, unique know-how and extensive experience with the production of VVER-unit components and advanced technologies, and operational service in the areas of nuclear power plant maintenance and refurbishment.

Our major contract is the comprehensive maintenance primary circuit equipment (the Reactor Building Logical Unit) in all Czech nuclear power units, i.e., four VVER 440 units at the Dukovany NPP and two VVER 1000 units at the Temelín NPP. ŠKODA JS provides service and maintenance of the primary circuit equipment in all units based on framework contracts since 2008. The currrent contract covers the period until 2030.

At Temelín NPP, we perform both standard scope activities within planned outages and a number of unplanned activities every year. In 2022, in addition to the standard disassembly and reassembly of the reactor for fuel exchange, we removed and disposed of over 30 sensors in the neutron flux measurement channels using our ŠKODA JS – device for removal, transport and disposal of thermocouples and neutron flux sensors, resealed selected control rod drive housings and cooperated in the use of a fuel assembly inspection stand for inspecting selected irradiated fuel assemblies removed from the reactor (designed, manufactured and tested by ŠKODA JS in cooperation with ČEZ). In addition to the reactor activities, we carried out the inspection of two steam generators, including inspections of heat exchanging tubes and technically complex reconstruction of N23 nozzles (chemical diagnostics inside the steam generator with instrumentation penetrating the steam generator casing), a number of repairs of weld joints and technical connections, revisions of the hydroaccumulators and the emergency aftercooling exchanger, as well as revisions and repairs of a number of valves, including fast-acting valves which, if necessary, can safely isolate the containment within a few seconds (preventing the release of radioactive substances from the containment). In 2022, as part of the unit shutdown, we carried out a unique reconstruction of the fire extinguishing system tank (total volume of the fire water tank is 78 m3), on site, using the technology of successive welding of the new tank plates, including prescribed inspections and tests..

At the Dukovany NPP, in 2018 we repaired a defect in the guide wheel and the pressure lid of the main circulation pumps, assembled a secondary thermal barrier on the main circulation pumps, replaced the bodies of the main safety valves of the pressurizer system, cleaned the bottom of the reactor pressure vessel, cleaned the reactor core bottom drop shock absorbers using a single-purpose device developed by ŠKODA JS, and performed a number of other activities.

Furthermore, we managed to secure the repair of the reactor after its overfilling in 2020, including the provision of expert opinions, preparation and production of fixtures for the inspection of control rod drives flange joints. We also managed to plan the repair of heterogeneous welded joints of the feedwater distribution system, which is very complicated due to the spatial arrangement and radiation load. Starting in 2022, we have repaired the main circulating pump distribution wheels using a robotic workstation. In 2021, we managed a unique project with the help of Framatome in which we cleaned the secondary side of the PG26 steam generator. After customer evaluation, we will continue this unique project on the other steam generators. We are now preparing for another very challenging project, namely the replacement of the control rod drives sleeve liner on the reactor of the first Dukovany unit. As a strong partner, by 2022 we have started to provide our own inspections on the RRCS drives, which until now have been provided exclusively by subcontractors. Under the leadership of Škoda JS, we are implementing other no less important technical and investment projects of smaller and larger scale.

We have confirmed our role as a stable and reliable partner for the operators of both Czech nuclear power plants (ČEZ, a. s.) in a number of complex and demanding repairs, including those of equipment and technological units located outside the primary circuit. The close and functional cooperation between the company’s key segments, Engineering – Production – Service, was also the basis for dealing with the many complex and demanding repairs and reconstructions that the operational life and shutdowns of a nuclear power plant entail in 2022. The cooperation of these three fundamental pillars of the company and the use of many years of experience, unique know-how and the support of other specialist departments guarantee that ŠKODA JS will be able to face the most demanding technical challenges in the years to come, not only in nuclear power plants but also in other sectors of the entire nuclear industry.

The history of our cooperation

2008a general contract concluded for the maintenance of the Reactor Building Logical Units in all units at the Dukovany and Temelín NPPs

2016the second general contract for the maintenance of the Reactor Building Logical Units in all units at the Dukovany and Temelín NPPs

2030is when the current general contract of the ’Reactor Building Logical Units’ maintenance expires