References

ŠKODA JS has been operating in the nuclear power industry since 1956. Our business is based on three basic pillars – engineering, production and service. Over the sixty plus years of our history, we have worked on a large number of projects in all three areas. We continually develop our skills and search for new opportunities. Currently, the largest project in which we are involved is “Completion of Units 3 and 4 at the Mochovce Nuclear Power Plant” in Slovakia.

Significant projects

Examples of our work on long-term projects, production and service contracts.

Units 3 and 4 at Mochovce NPP, Slovakia

- The final supplier of the primary circuit and the fuel-handling part in both units under construction

- Currently in the role of supplier of the power plant’s essential operating systems – the primary circuit, the fuel handling part, connecting pipes, intermediate cooling circuits, parts of the instrumentation and control system, and maintenance workshops.

- One of the five main suppliers

- Expert support provided to the investor in the areas of engineering, planning, licensing support, construction and assembly works and commissioning

- Strength, seismic and lifetime calculations

NPP decommissioning projects

- Removal of steam generators

- Transport of pressure vessels and reactor internals

I&C system refurbishment or replacement projects

- Dukovany NPP (2002-2017)

- Paks NPP, Hungary (2015-2019)

- Metsamor NPP, Armenia (2017-2019)

- Temelín NPP (2011-2016)

Casks for the transport and storage of spent nuclear fuel

- The cask for VVER 1000 reactor fuel – ŠKODA 1000/19

- The cask for VVER 440 reactor fuel – ŠKODA 440/89

- Cask VPVR

- Special casks

- Cask transfer equipment

- Equipment for the removal and disposal of sensors

Nuclear power plants in Ukraine

- Investment projects

- The capping of channels of ionization chambers – equipment production, assembly supervision, and training for operating staff

- Emergency containment depressurization (Venting)

- The project of refurbishment of a part of the I&C systems – a unified technology set for the Zaporozhye NPP

Control rod drives

- Dukovany NPP, Temelín NPP

- Jaslovské Bohunice NPP, Mochovce NPP, Slovakia

- Paks NPP, Hungary

- Ukrainian NPPs

Comprehensive maintenance of the primary circuit equipment

- General partner for comprehensive repairs and maintenance since 2008

- Dukovany and Temelín NPPs

Dukovany nuclear power plant, Czech Republic

- The final supplier of the primary circuit and the fuel-handling part in all four units at the nuclear power plant

- General contractor for the unique project of the complete I&C systems replacement in full operation

- Reconstruction of the ancillary switchboards

- Strength, seismic and lifetime calculations

Temelín nuclear power plant

- The final supplier of the primary circuit and the fuel handling part in both units

- Control system refurbishment projects

- Strength, seismic and lifetime calculations

- The capping of channels of ionization chambers – equipment production, assembly supervision, and training for operating staff

Units 1 and 2 at Mochovce NPP, Slovakia

- The final supplier of the primary circuit and the fuel handling part in both operated units

- Construction documents

- Component production and assembly

- Assembly on site

- Commissioning

Paks nuclear power plant, Hungary

- Reactor production and assembly supervision in all four units of the nuclear power plant

- General contractor for the project of instrumentation and control system replacement

Bohunice V2 nuclear power plant

- The final supplier of the primary circuit and the fuel handling part

- Calculations – the Scorpio reactor core monitoring system

Design

- Spatial coordination at the Mochovce and Dukovany NPPs

- Modernization of the polar bridge crane in Units 1 and 2 at the South Ukraine NPP

- Emergency containment depressurization (Venting) at Ukrainian nuclear power plants

- Cask for leaky spent fuel for the Temelín NPP

- Deep disposal - end of fuel cycle

- Science and research

- Hněvkovice Hydroelectric Plant

Mechanical Design

- Complex engineering activities – conducting studies and preparing construction documents, calculations, production technical drawings and calculations

- Support for the assembly of the piping systems at the Mochovce NPP

- The “Reconstruction of the Main Pipelines and Safety Valves of the Pressurizer System” project at the Temelín NPP

- The “Emergency Containment Depressurization (Venting) at Ukrainian Nuclear Power Plants” project

- Development of new hermetic penetrations

Calculations

- Strength and lifetime

- Radiation safety

- Thermo-hydraulics

- Physics

Research, training and experimental reactors

- Experimental, research and training reactors

- Complete turnkey projects

- Reactor control system refurbishment

Equipment for PWR- and BWR-type nuclear power plants

- Reactor internals

- Cask transfer equipment

- Tools and manipulators

Spent fuel storage in spent fuel pools at nuclear power plants

- Compact storage racks

Tighteners

- Reactor main flange joint stud tensioners

- Tightening units for reactor upper block flange joints

Repair of a heterogeneous weld joint

- General contractor for a unique repair

- Preparation, tests, calculations and implementation

- Dukovany and Temelín NPPs

Device for removal, transport and disposal of thermocouples and neutron flux sensors

- Transport and disposal of thermocouples and neutron flux sensors from VVER 440 reactors

- Transport and disposal of thermocouples and neutron flux sensors from VVER 440 reactors

Neutron flux measurement channels

- Neutron flux measurement channels for VVER 440 reactors

- neutron flux measurement channels for VVER 1000 reactors

Loviisa nuclear power plant, Finland

- Delivery of equipment and components – intermediate rods for control rod drives and reactor control equipment, fuel assembly components

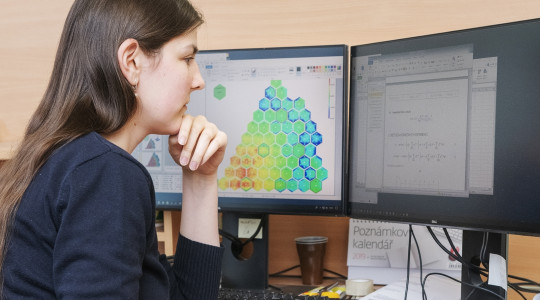

CMIS.CE System

- Configuration and preparation of “smart data”

- Management, validation and exchange of data between subcontractors, the general contractor and the customer

- Developed by ŠKODA JS in cooperation with the Hexagon Company