Equipment for PWR- and BWR-type nuclear power plants

For more than 30 years, we have operated in the market of PWR and BWR-type nuclear power plants. Our entry into this market required the necessary certifications such as ISO, ASME, DIN, CEFRI and others. We have gradually worked our way to the role of a qualified supplier of nuclear equipment to the main contractors and operators of nuclear power plants in Europe, the USA and the Far East. The company can manufacture equipment according to the customer’s documentation as well as develop and manufacture entirely new equipment based on a basic design assignment.

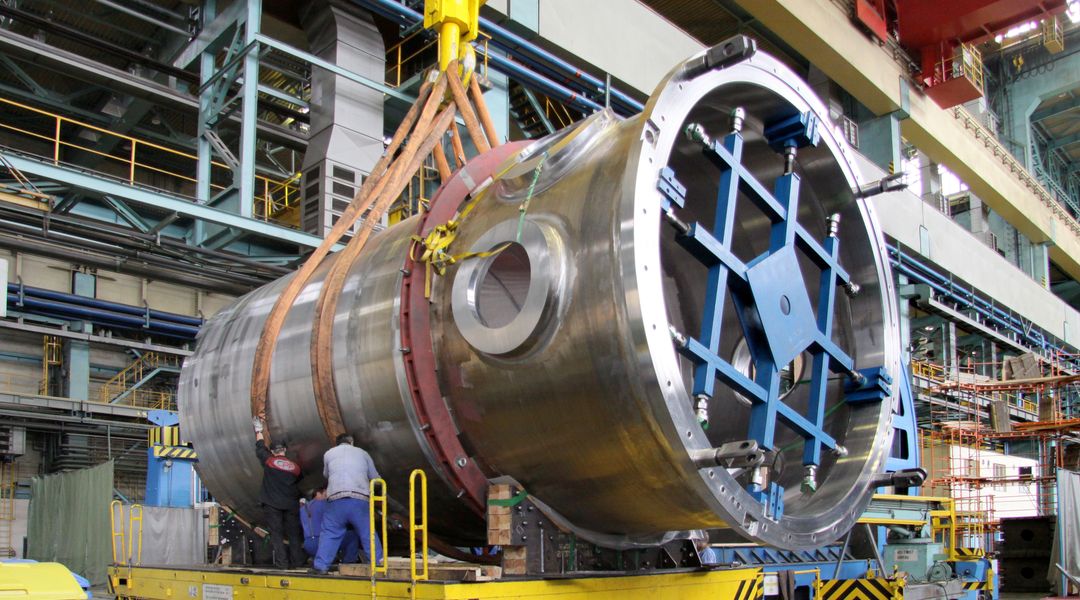

PWR and BWR reactor internal parts

Production of reactor internals for nuclear power plants using PWR (pressurized water reactors) and BWR (boiling water reactors) represents the main scope of equipment supplies by ŠKODA JS a.s. In 1999, we supplied two sets of modernized boiling water reactor (BWR) internal parts for the Swedish Forsmark nuclear power plant. The equipment included the core support grid and shroud for each unit. These contracts were part of a program for improvements in the safety and effectiveness of BWR nuclear power plants.

An important project for ŠKODA JS was the manufacture of internal parts and a support ring for a newly constructed pressurized water EPR-type reactor (III+ generation pressurized water reactor) at the Olkiluoto NPP, Finland. The customer, Areva NP, now Framatome, also ordered a Lifting device for handling EPR reactor internalsfor the same project. Based on good references from this project, ŠKODA JS supplied to the same customer a complete set of the EPR reactor internal parts for Unit 1 for the newly built Taishan NPP, China.

In 2018, ŠKODA JS concluded a contract with the company Framatomefor the production and supply of two sets of the reactor internals for the 1600 MW EPR reactor at the Hinkley Point C NPP in Somerset County, UK. The delivery includes in particular: core barrel, heavy reflector and upper internals. The first set was delivered to the construction site in early 2024.

Flange joint stud tensioners

A stud tensioner is a fully automated device that operates the main flange joint of the reactor, meeting extreme requirements for accuracy, speed and functional reliability.

Based on the contract concluded with the main contractor, GE Nuclear Energy, ŠKODA JS designed, manufactured and supplied two sets of reactor main flange joint stud tensioners to the newly constructed Lungmen NPP in Taiwan.

Special structures

Apart from the aforementioned reactor parts, ŠKODA JS develops and produces other equipment for nuclear power plants with PWR- and BWR-type reactors.

In 2000, four hydrogen recombiners were supplied to the Lungmen nuclear power plant in Taiwan (ABWR).

In 2002, a heat exchanger for the spent fuel storage pool was supplied to the Krsko nuclear power plant in Slovenia. This device was produced according to the ASME Code, Section III.

Equipment for the transport of fuel

Over more than 30 years of our activities in the area of PWR and BWR reactors, ŠKODA JS has built a reputation as a reliable supplier that can design,, manufacture and commission highly sophisticated nuclear equipment.

After a successful audit, ŠKODA JS a.s. became a qualified supplier for the French company EDF, with whom a contract was signed for the supply of spent fuel cask transfer facility for the Unit 3 of the Flamanville NPP. The equipment was handed over to the customer in 2017. The scope of supply included equipment design, detail design, manufacture, on-site installation and commissioning.

The history of the project

1991-1993reconstruction of 13 sets of the main condensate filters at the Olkiluoto NPP/1,2 (BWR), Finland

1993reactor pressure vessel support ring produced and supplied to the end user Civaux 1 NPP (PWR), France)

1999delivery of BWR reactor internal parts – 2 sets (core support grid and shroud) for ABB Atom (end user Forsmark NPP, Sweden)

2002reactor main flange joint stud tensioner of ŠKODA JS’ design for the Lungmen NPP (ABWR), Taiwan

2008reactor pressure vessel support ring for the Olkiluoto NPP/3 (EPR), Finland

2010lifting device for handling reactor internal parts for the Olkiluoto NPP/3 (EPR), Finland

2010reactor internal parts for the Olkiluoto NPP/3 (EPR), Finland

2012reactor internal parts for the Taishan NPP/1 (EPR), China

2017ŠKODA JS’s own designed spent fuel cask transfer facility for the Flamanville NPP/3 (EPR), France

2018contract concluded for the production and supply of two sets of reactor internals for the Hinkley Point C NPP/1,2 (EPR)

2024the first set delivered to the construction site at Hinkley Point C NPP/1