Mechanical Design

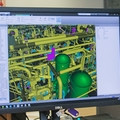

Since 2014, ŠKODA JS a.s. has expanded its portfolio to include “Piping Systems Engineering”. With opening this new design workplace in Prague, ŠKODA JS a.s. has expanded its competence in the field of piping systems, including comprehensive engineering activities from the elaboration of studies and detailed designs, through the preparation of calculations, to the development of production drawings and calculation documentation.

This office employs a team of experienced designers and calculators who previously worked mainly for the project “Completion of Units 3 and 4 of the Mochovce Nuclear Power Plant”.

Its team members are mostly experienced specialists, some of whom have worked in the power industry for decades. Over the years, however, we have also managed to attract young colleagues who have already gained experience in the independent processing and management of large-scale projects.

The great advantage of this department is that not only designers but also specialists in pipeline strength calculations can work very closely together on contracts. This combination has proven to be particularly advantageous because even in the age of electronic communications, there is nothing better than being able to have a designer and a calculator working literally in the same office.

Since 2014, the Piping Systems Department has been working on the project “Completion of Units 3 and 4 of the Mochovce Nuclear Power Plant”. The designers are mainly involved in resolution of collisions, including performing operational control calculations of piping and its accessories. Not only the Unit 3 has been successfully completed, but also all updates of the as-built documentation and the equipment have been handed over to the operator for physical and later for energy start-up. On Unit 4, installation is complete and the as-built documentation is being prepared.

The team of designers also successfully continued in the realization of other projects, mainly for Czech nuclear units.

In Dukovany NPP, we finished the following projects:

- Primary circuit safety valves reinforcement

- Main safety valves reconstruction

- Recalculation of super emergency supply piping routes

- Proven calculation documentation of essential technical water reconstruction

- Documentation of the “as-built” state and strength calculations of steam and power supply piping in the Dukovany NPP engine room.

- Reconstruction of the essential technical water piping at the boundary of the hermetic zone with the addition of shut-off valves and replacement of hermetic penetrations

- First stage of the project to replace HTG joints with flange joints on steam generator (SG) condensate vessels

- Assessment of the extension of the annual interval for in-service inspections

- Feasibility study – exchange of steam generators

In Temelín NPP, we finished the following:

- Reconstruction of the piping and main safety valves of the volume compensation system including calculation of the hydrogen removal system

- Proven calculation documentation of the essential technical water reconstruction

- For AF-Consult Czech Republic s.r.o. we performed a series of calculations of piping components for the Brazilian Angra III project.

- Replacement of the control valve on the injection into the volume compensator at Temelín NPP

- Hydraulic calculation of non-essential technical water

- Strength calculations for essential technical water reconstruction

- Design and supply of steam test stand parts for Temelín NPP.

- Reconstruction of the fire water tanks in the A820 room

- Feasibility study and initial design for the fast depressurization of the primary circuit in the event of a severe accident

- Replacement of the sleeve on the Main Circulation pipeline

- Design and calculations – refurbishment of high pressure fire extinguishing pumps

- Design and calculations for long-term heat removal (G840)

Other activities – for companies Slovenské elektrárne, a.s., ČEZ, a. s., I&C Energo a.s., Institute of Applied Mechanics in Brno, s.r.o., and NAEK Energoatom (Ukraine):

- Development of new hermetic penetrations for the Akkuya NPP (Turkey) and Hanhikivi NPP (Finland)

- Seismic reassessment of major components for Mochovce NPP, including the start of work on implementation projects.

- Extensive feasibility study for the replacement of measuring orifices and nozzles on the engine room for Mochovce +,2

- Calculations and design for the attenuation of high pressure fire pumps at Mochovce NPP

- First stage of the project for replacement of measuring nozzles and separators at Mochovce NPP.

- Sensitivity analysis, calculation report and technical report – elimination of oscillation of the main circulation pump at Bohunice NPP.

- Strength calculation for the project “Solar Energy Concentration”.

- Design and supply of emergency containment depressurization (Venting system) at Ukrainian nuclear power plants.

The history of our cooperation

2014ŠKODA JS opened a new mechanical design office in Prague

since 2015we have been working on the “Completion of Units 3 and 4 at the Mochovce Nuclear Power Plant” project

2015-2017the project “Reconstruction of the Main Pipelines and Safety Valves of the Pressurizer System Including the Hydrogen Removal System Calculation” at the Temelín NPP

2015the projects “Reconstruction of the Main Safety Valves” and “Reinforcement of the Primary Circuit Safety Valves” at the Dukovany NPP, and the project “Supporting Documentation Calculation of the Essential Service Water Reconstruction” at the Temelín NPP

2016the projects “Emergency Feedwater System Pipelines Calculation” at the Dukovany NPP and the project “Supporting Documentation Calculation of the Essential Service Water Reconstruction” at the Temelín NPP

2017the projects “Replacement of the Injection Control Valve in the Pressurizer System”, “Hydraulic Calculation of Non-essential Service Water at the Temelín NPP”, “Strength Calculations for Additional Essential Service Water Reconstruction” at the Temelín NPP; design of the new Venting system at the Zaporozhye NPP (Ukraine), development of new hermetic penetrations for a bid for the Akkuyu NPP (Turkey) and the Hanhikivi NPP (Finland)

2018-2020projects for the companies Slovenské elektrárne, a.s., ČEZ, a. s., I&C Energo a.s., the Institute of Applied Mechanics Brno, and NAEK Energoatom (Ukraine)

2021-2022completion of documentation of the “as-built” state of Mochovce 3 before handover to the operator, solving the issue of FEBE supplies to Mochovce 3,4, documentation of the “as-built” state of the Dukovany engine room, implementation of the reconstruction of the fire water tanks of Temelín NPP, implementation of the project for the reconstruction of the essential technical water piping at the boundary of the hermetic zone with the addition of shut-off valves and replacement of hermetic penetrations. Assessments, calculations and tests for the replacement of heterogeneous joints on the SG condensation vessels with flanged joints. Project for the long-term heat removal at NPP Temelín. Preparation of a large number of technical parts of various tenders.