Units 3 and 4 at Mochovce NPP, Slovakia

The Completion of Mochovce NPP is currently our biggest project

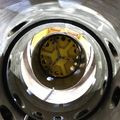

Completion of Units 3 and 4 at the Mochovce Nuclear Power Plant is currently our biggest engineering investment project. We produced and delivered both complete VVER-440 reactors. At this time, we act as the supplier of not only the power plant’s essential operating systems, i.e., the primary circuit and fuel handling part, but also connecting pipes, intermediate cooling circuits, parts of the instrumentation and control system, and maintenance workshops. This contract is very beneficial for us in terms of the maintenance and development of invaluable experience in managing large investment projects.

We are one of the five main suppliers. The contract for the delivery of the key primary circuit and fuel handling systems was concluded with Slovenské elektrárne, a.s. in 2009. In the following years, addenda to the contract were signed, which officially confirmed an extension of the entire contract and an increase in the volume of assembly works as well as the scope of services provided by ŠKODA JS.

The design, delivery, assembly and cold start-up stages at Unit 3 have been completed. Successful completion of the cold and hot hydrostatic test programs confirmed the high quality of provided assembly works. Thereafter, the stage program of the so-called complex inspection was launched, which was completed by the loading of nuclear fuel, which started the phase of physical and power start-up. The third unit of the Mochovce NPP has been connected to the grid and started to supply 100% of its power in September 2023. After a successful 144-hour trial run in October 2023, the works on Unit 3 were completely concluded and the Unit was handed over to the customer.

Activities leading up to the completion of works and the commissioning continue at the Unit 4. A sequence of cold tests and stage programs is currently in progress, identical as those at Unit 3.

Throughout the construction process, ŠKODA JS provides the investor with specialists in key areas, such as engineering, planning, licensing support, construction and assembly works and start-up.

The history of our cooperation

The timeline of our cooperation on Units 3 and 4 at Mochovce NPP

2009 ŠKODA JS and Slovenské elektrárne signed a contract for the completion of Units 3 and 4 at Mochovce NPP

2010 a reactor pressure vessel, produced by ŠKODA JS, was installed at Unit 3

2011 we developed and supplied a special cask of our own design, KSV 440, for witness samples of pressure vessel steel at Units 3 and 4

2013 we developed and supplied equipment of our own design for the removal, transport and disposal of neutron flux sensors and thermocouples from the VVER 440 reactor

2013 ŠKODA JS and Slovenské elektrárne signed an addendum to their contract to extend the project and increase the volume of work and services provided by our company

2017 we completed the control assemblies of reactor internals at Unit 4

2018 cold hydrostatic testing was performed and the program of hot hydrostatic testing commenced at Unit 3

Assembly works are under way at Unit 4 to be followed by construction tests

2019-2020 hot hydrostatic test program and complex inspection were performed at Unit 3

2022fuel loading into Unit 3, start of physical start-up

2023increasing the output of Unit 3 gradually up to 100%

14. 10. 2023

successful 144-hour proven operation of Unit 3, handover to the investor