Research, training and experimental reactors

There are three research reactors in operation in the Czech Republic, supplied by ŠKODA JS. Two research reactors, LVR-15 and LR-0, operate at the Nuclear Research Institute Řež, , and there is also a training reactor VR-1 operated by the Faculty of Nuclear Sciences and Physical Engineering in Prague. All these reactors use enriched uranium for fuel and light water for reactor core moderation and cooling. Research reactors are used for nuclear fuel testing, material engineering, irradiation experiments, the production of radioisotopes for the healthcare industry, validation of calculation codes, and testing of neutron detectors and measuring equipment. Reactors vary in terms of their power output and construction, which is designed with respect to their required purpose.

ŠKODA JS has designed and supplied a total of 5 such reactors. The projects included design, production, delivery, assembly, commissioning and maintenance.

The first project of this kind was a ŠR-0A light-water experimental reactor, which we delivered in 1970 and which was later rebuilt into an experimental light-water reactor, ŠR-0. It was installed not far from Pilsen, at a ŠKODA facility in Vochov. It was decommissioned in 1989.

Next in the series was the experimental heavy water subcritical reactor ŠR-0B, delivered in 1971 to the Czech Technical University in Prague, where it was operated until 1978. This was followed by the design and delivery of the large critical heavy water experimental reactor TR-0 to the ÚJV Řež in 1972. The reactor was decommissioned in 1980. and two years later we completed its rebuilding into the large critical light water experimental reactor LR-0, which is still in operation today.

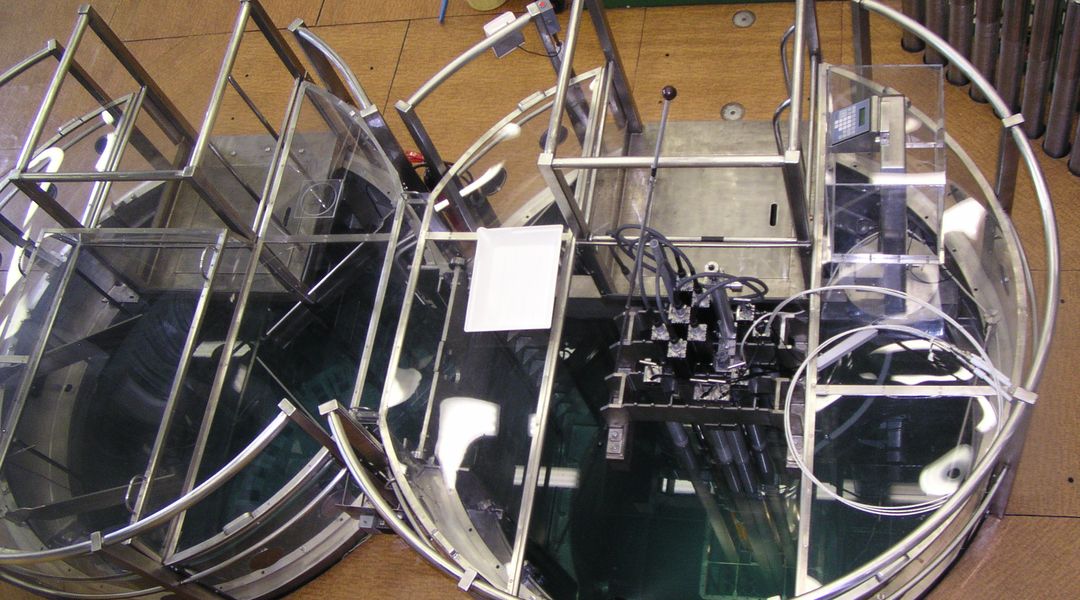

The following projects involved deliveries of an experimental light-water research reactor, LVR-15, for the Nuclear Research Institute Řež (1989) and a training light-water experimental reactor, VR-1, for the Czech Technical University in Prague (1990). Both reactors are in use to this day. In 2006, we innovated the independent power protection channels, and in 2008 we refurbished the control system of an LR-0 reactor. In the same year, we supplied a supercritical water loop to the Nuclear Research Institute Řež and carried out its assembly; the equipment is still in operation to this day.

Since 2014, we have successfully expanded our activity in the area of research reactors outside the Czech Republic.

For our Belgian customer SCK-CEN, we produced and supplied more than 150 main and hundreds of smaller stainless steel internal parts for the BR2 research reactor, for which there were very strict requirements for accuracy. To our customer in the USA, we supplied a total of 12 control rod drives of our own design for the WWR-K light-water research reactor in Kazakhstan. We also produced control rod drives of our design for the Atominstitut in Austria, which operates the TRIGA research reactor in Vienna. Part of this project was also the refurbishment of the reactor instrumentation and control system.

We supplied and continue to work on other projects for ITER – a nuclear fusion reactor under construction in Cadarache in the south of France. These included, for example, the production of a 1:1 scale dummy and feasibility verification of a technical solution of reactor upper nozzle flanges; a design study of the process of tightening bolted joints between the portal of the vacuum vessel and the plugs; development of the production process for the ITER vacuum vessel seal and verification using a vacuum/pressure test (design, production and testing of a 1:1 scale model); the new design of a manipulator for inserting and removing portal plugs into/from a test vessel installed at Cryogenmash, Russia. The portal plugs weigh as much as 48 tons!

Between 2014 and 2022, we implemented a contract for the development and delivery of control rod actuator position sensors (IPMAB system) together with a control rod actuator motor control system (EXMAB system) for a research reactor in Brazil. The entire contract was implemented in several stages:

- development of the technical design and concept verification,

- prototype production and functional testing at ŠKODA JS,

- equipment qualification, • production and delivery of the final equipment

The final, fifth stage of installation and commissioning will be completed according to the Brazilian customer’s plan in 2026.

The history of our cooperation

1970design and delivery of the first experimental reactor, ŠR-0A, which in 1975 was rebuilt into an experimental light-water reactor, type ŠR-0

1982commissioning of a large critical light-water experimental reactor, LR-0, which had been rebuilt from a TR-0 reactor

1989design and delivery of an experimental light-water research reactor, LVR-15

1990design and delivery of a research and training light-water experimental reactor, VR-1

2006innovation of independent power protection channels at a VR-1 reactor

2008delivery and assembly of a supercritical water loop

2014-2015

a model produced for the purpose of feasibility verification of a technical solution of reactor upper nozzle flanges at the ITER reactor (France)

2015delivery of 158 main and hundreds of smaller stainless steel internal parts for a BR2 reactor (Belgium)

2015development and delivery of control rod drives for a WWR-K research reactor in Kazakhstan

2015refurbishment of the reactor instrumentation and control system and delivery of control rod drives for the TRIGA research reactor in Vienna

since 2014various design projects for the ITER nuclear fusion reactor in France, e.g., 2018 – new design of a manipulator for inserting and removing portal plugs into/from a test vessel installed at Cryogenmash, Russia

since 2018Control Rod Drive Position Indicators project for a research reactor in Brazilia